Lithium-ion battery

锂离子二次电池 / Lithium-Ionen-Batterie / 리튬 이온 배터리

A rechargeable battery that utilizes the movement of lithium ions between the positive and negative electrodes

Batteries for electric vehicles, electric bicycles, laptop computer, mobile phones, renewable energy, etc.

Manufacturing process (for Active materials)

※This process is just one example, and the manufacturing methods vary by company.

※The following processes vary depending on the type of active materials. For example, in some cases, drying and calcination are performed after wet milling.

Manufacturing process (for Electrode materials)

※This process is just one example, and the manufacturing methods vary by company.

※The following manufacturing process can be applied to both cathode and anode materials.

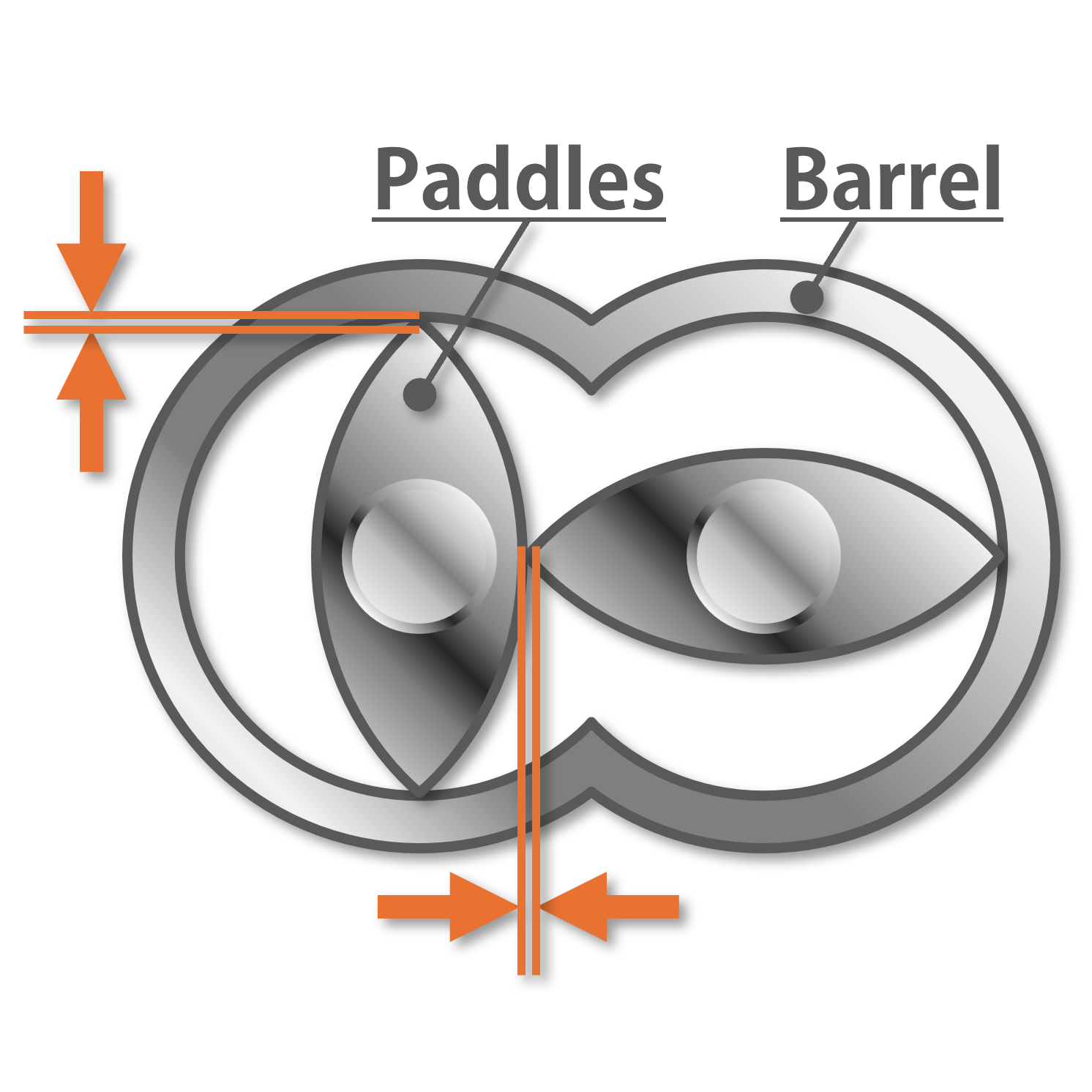

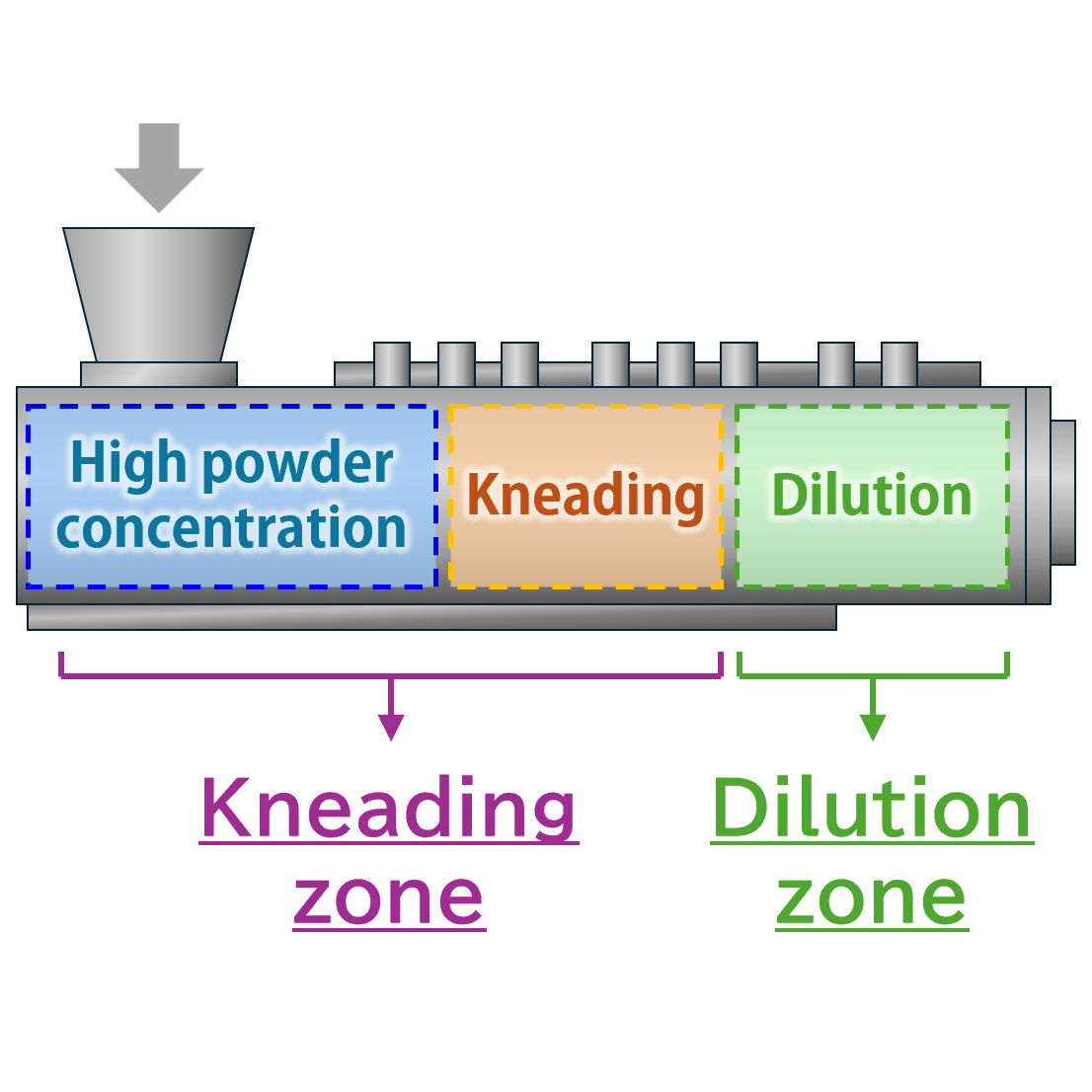

To achieve high-density electrodes, it is necessary to ensure high dispersion of the conductive additive and to disintegrate secondary agglomerated particles using high shear force. In addition, to keep the kneaded material temperature below the solvent’s boiling point, the heat generated during kneading must be removed.

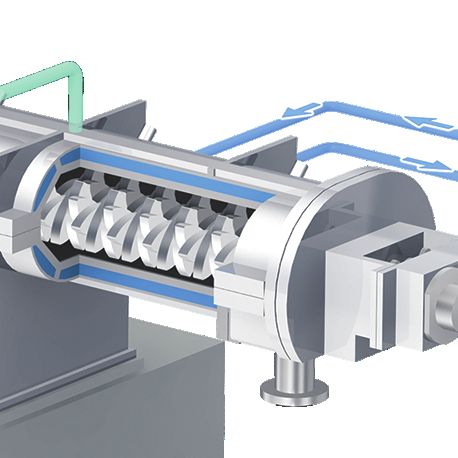

The twin-screw continuous kneader “KRC Kneader” can disintegrate secondary agglomerates while suppressing kneading heat, by the following mechanical characteristics and kneading conditions.

Removal of kneading heat by cooling through the jacketed barrel

High shearing force generated by paddles with small clearances

Design of a kneading zone with high powder concentration and a dilution zone

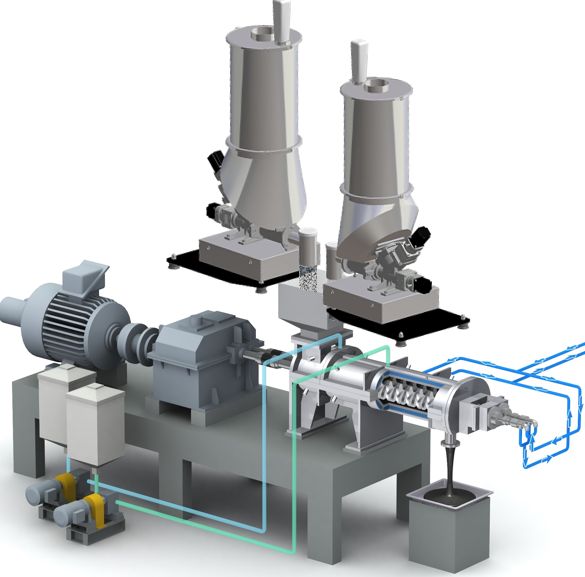

We are currently doing joint-development on a “Continuous Production System for Secondary Battery Electrode Slurry” with Kubota Corporation.

By combining the constant-rate feeding capability of a gravimetric feeder with the twin-screw kneader’s ability to achieve uniform mixing in a short time, we aim to contribute to the stable supply of secondary batteries—supporting the advancement of electrification and the realization of a carbon-neutral society.

drying