Since 1972, Kurimoto has been selling VOC exhaust gas treatment equipment that uses palm shell activated carbon as an adsorbent, contributing to the reuse of solvents and the reduction of load on the environment.

In addition to selling these equipment alone, we can also propose systems that combine them with Kurimoto’s specialty continuous powder process equipment.

Since 1972, Kurimoto has been selling VOC exhaust gas treatment equipment that uses palm shell activated carbon as an adsorbent, contributing to the reuse of solvents and the reduction of load on the environment.

In addition to the sale of these equipment alone, we can also propose systems that combine them with Kurimoto’s specialty continuous powder process equipment.

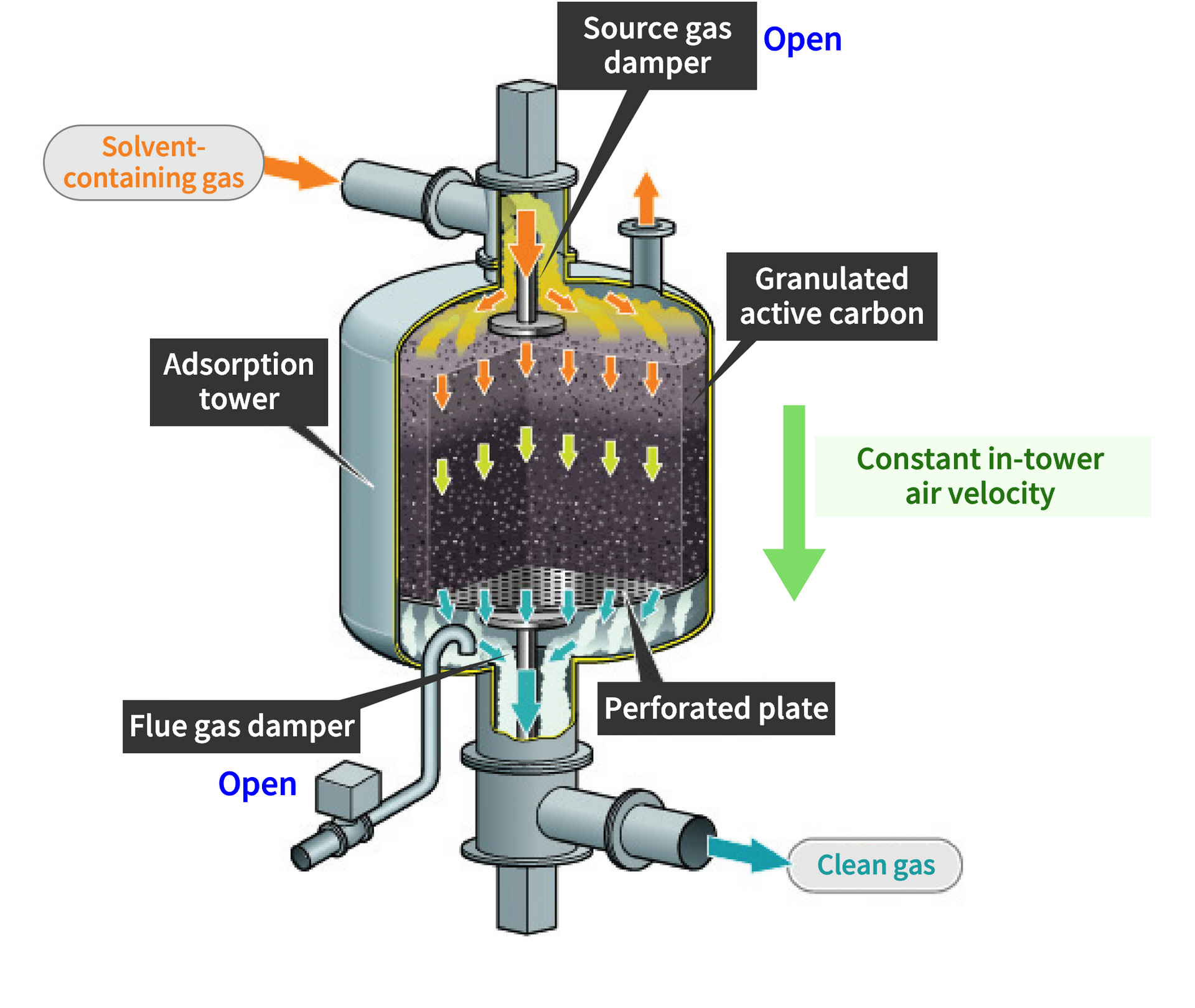

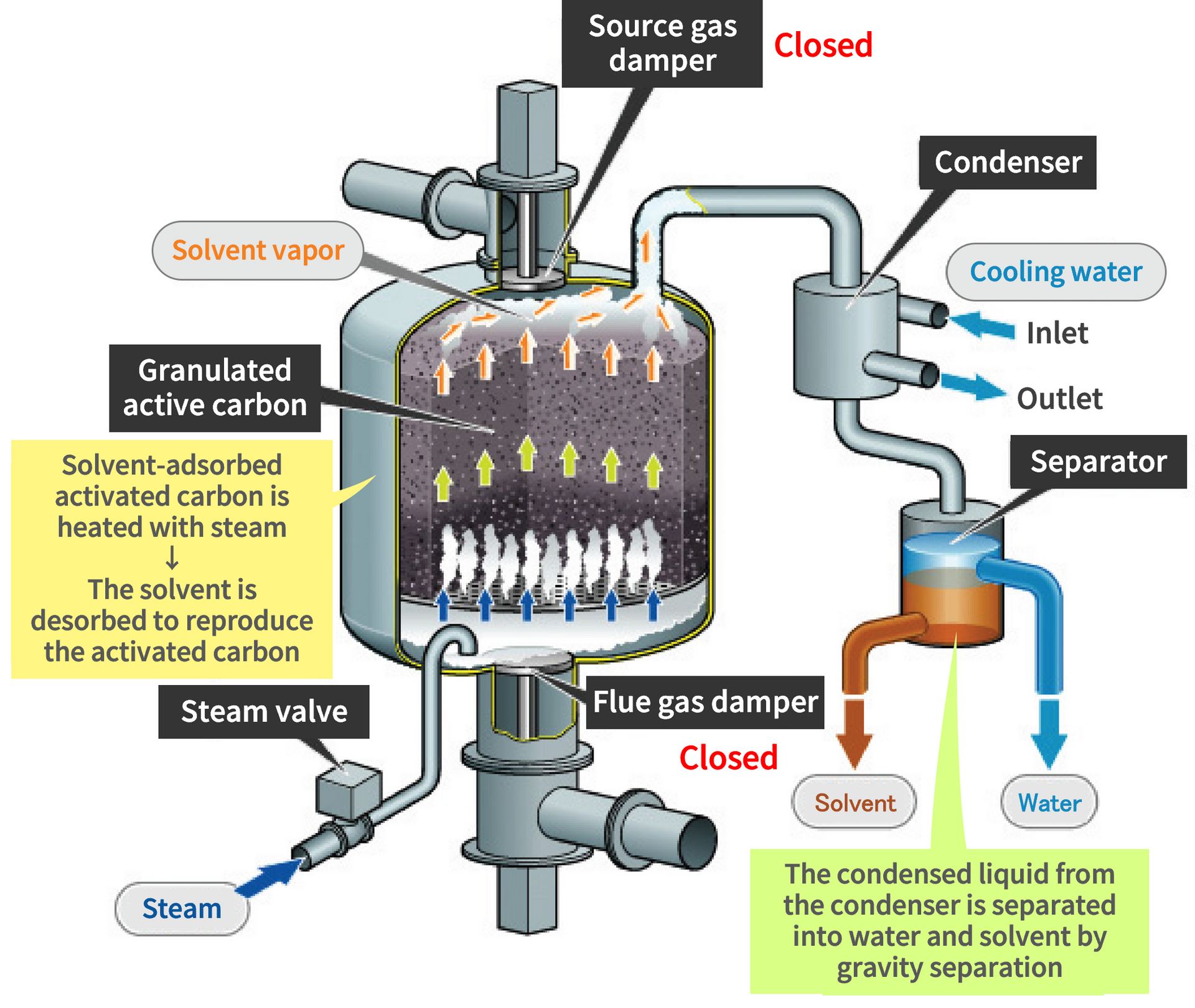

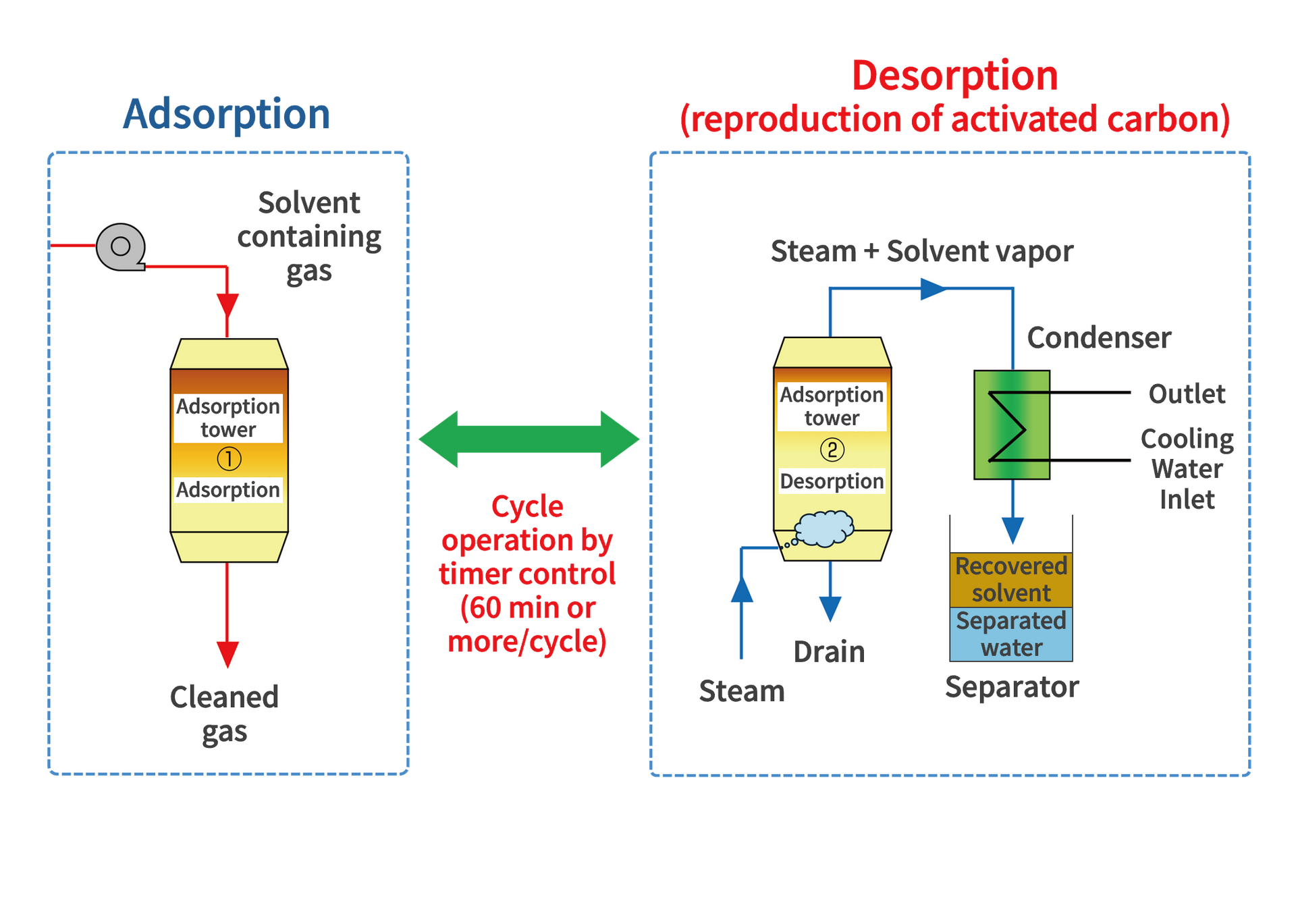

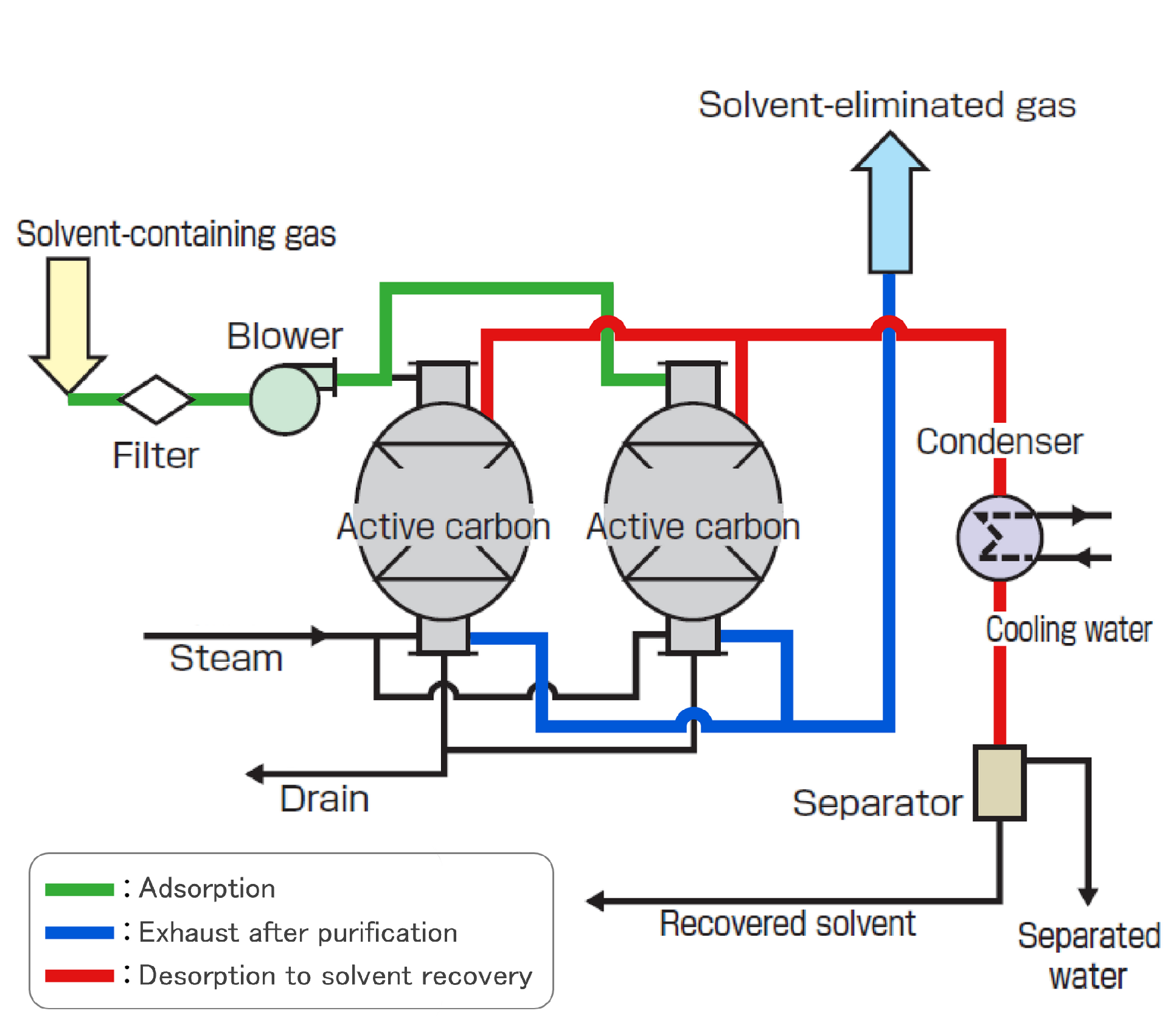

Steam desorption type solvent recovery system

The system can handle a wide range of air volumes from small to large.

PSA type solvent recovery system

See this system, which does not use steam for desorption, in the case of soluble or mixed solvents where the exhaust air volume is 0.75 m3/min or below.

(This system type is not designed for chlorine base solvents.)

- A high removal rate and adaptable to concentration changes

- Compatible with wide variety of solvent gases

- Less breakdowns and machine troubles

- Easy maintenance

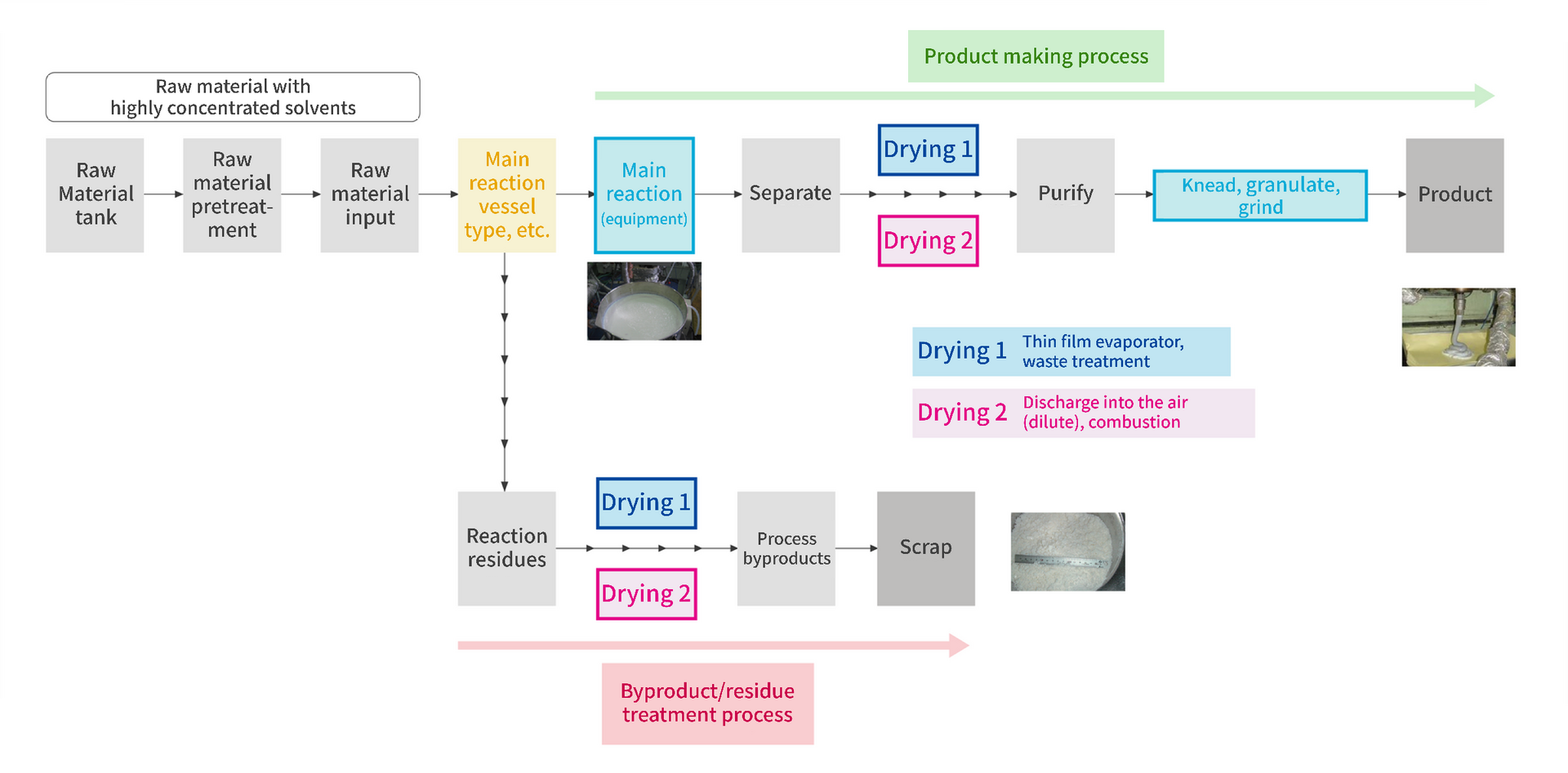

Proposal for systemization with Kurimoto’s powder processing equipment

- Treatment of volatile gases from high-concentration solvent dryers(SCPD)

- Treatment of volatile gases from reaction equipment(HB Reactor)

Contribution to sustainability

Chemical field

- Solvent/monomer recovery in chemical reaction of polymerization

- Solvent removal recovery such as resin solvents

- Solvent recovery in resin coat drying, etc.

Life science field

- Solvent recovery in manufacturing of pharmaceuticals or their intermediates

- Odor removal from research facilities, hospitals, etc.

Recycling field

- Solvent recovery from metal degreasing cleaners

- Volatile content recovery from solvent storage tanks, etc.

Drying process in a chemical plant process flow example

Steam Desorption type Solvent recovery system Summary

After the isolation process, the aqueous activated carbon is dried through hot air or solvent-containing gas, thus completing the reproducing cycle.

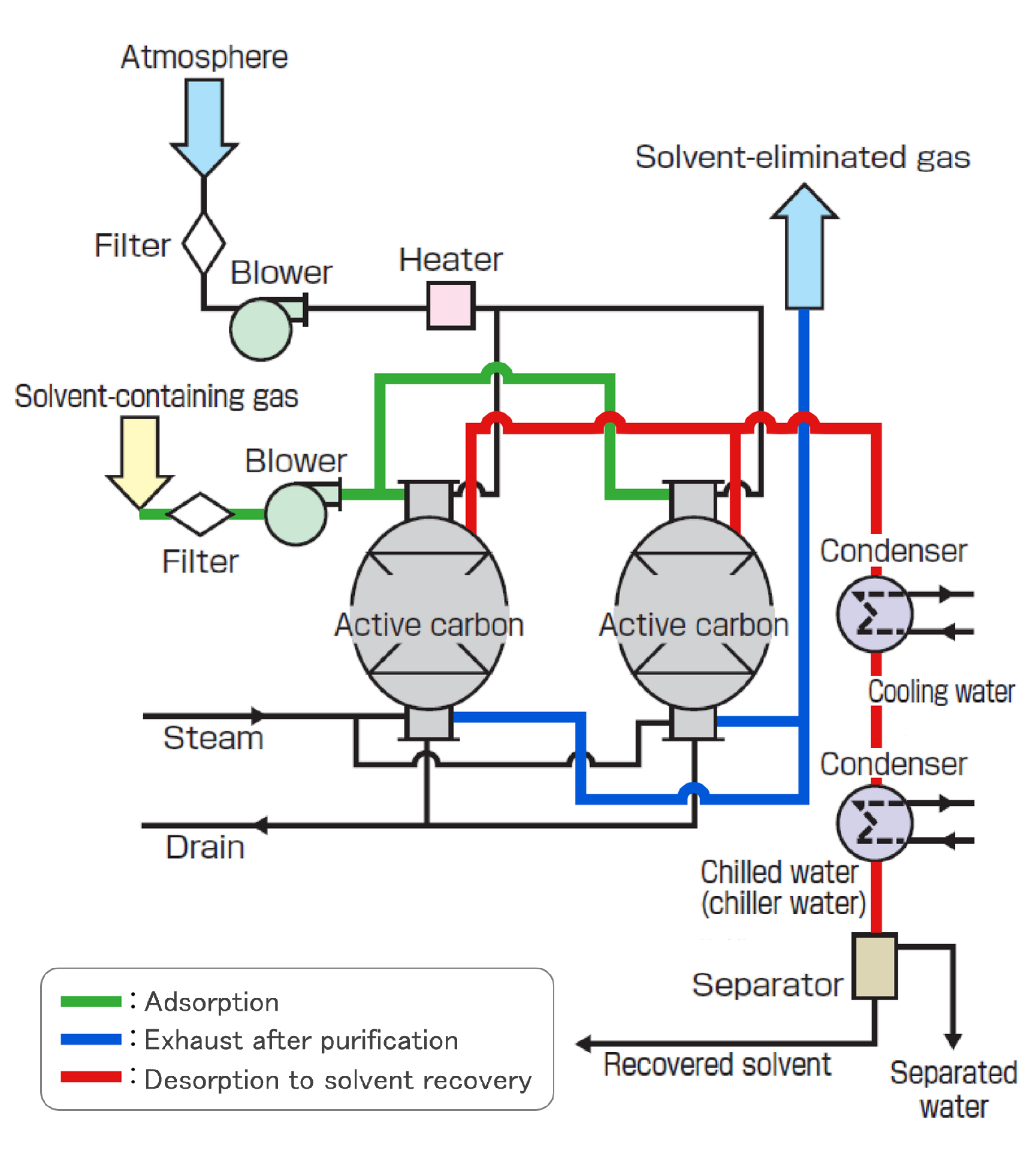

Steam Desorption type Solvent recovery system Basic Flow

■DA Type=For general-purpose solvents

■2BDA Type=For low boiling point solvents

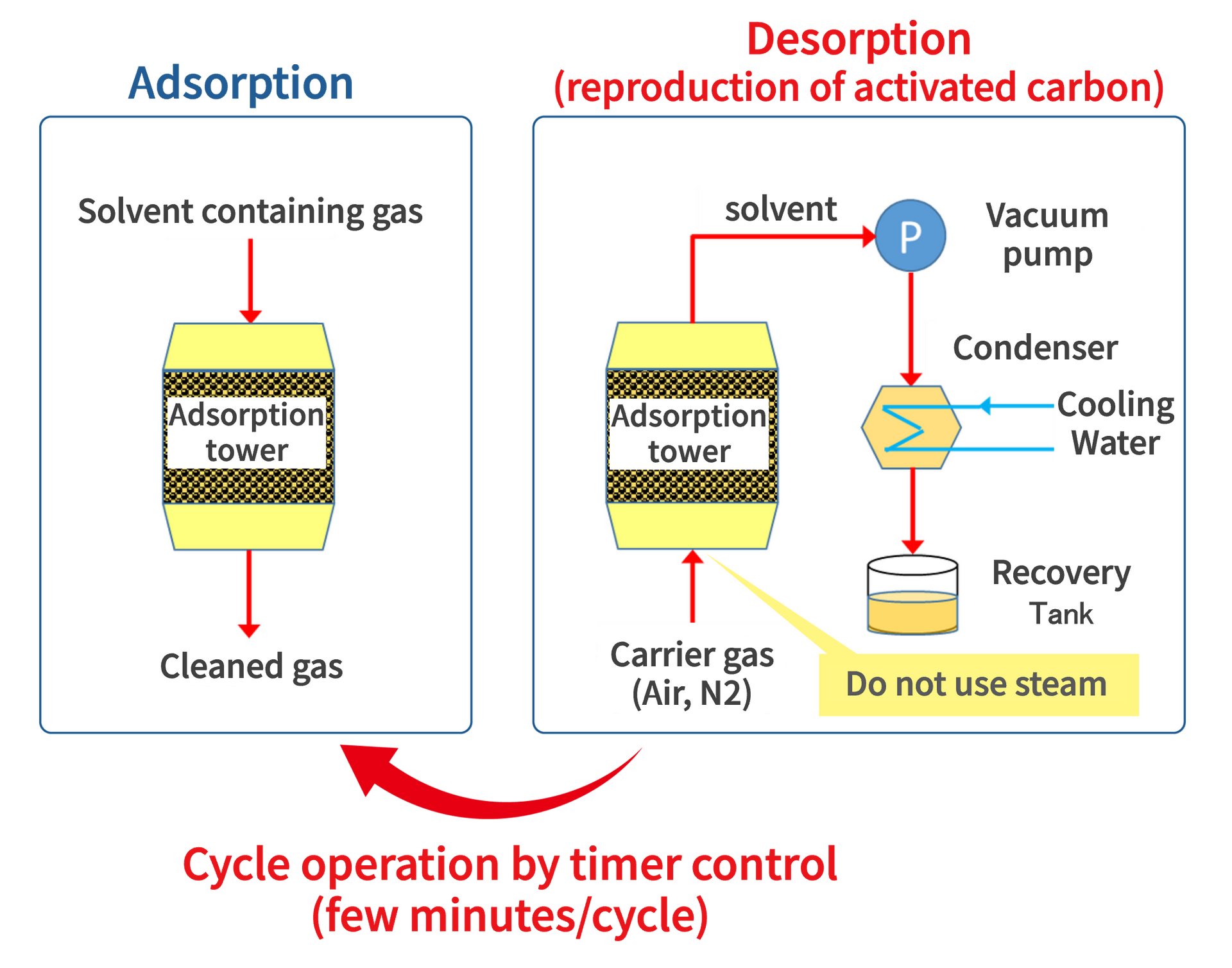

Pressure Swing Adsorption(=PSA) type Solvent recovery system Summary

- Kurimoto is the only company that uses granulated active carbon as an adsorbent in PSA type solvent recovery

- Compatible with wide variety of solvent gases

- Can support substantial changes in inlet gases concentration

- Remarkably less wastewater than with steam desorption type systems

- Low cost for adsorbent upkeep

- Less breakdowns/machine troubles due to less driving devices

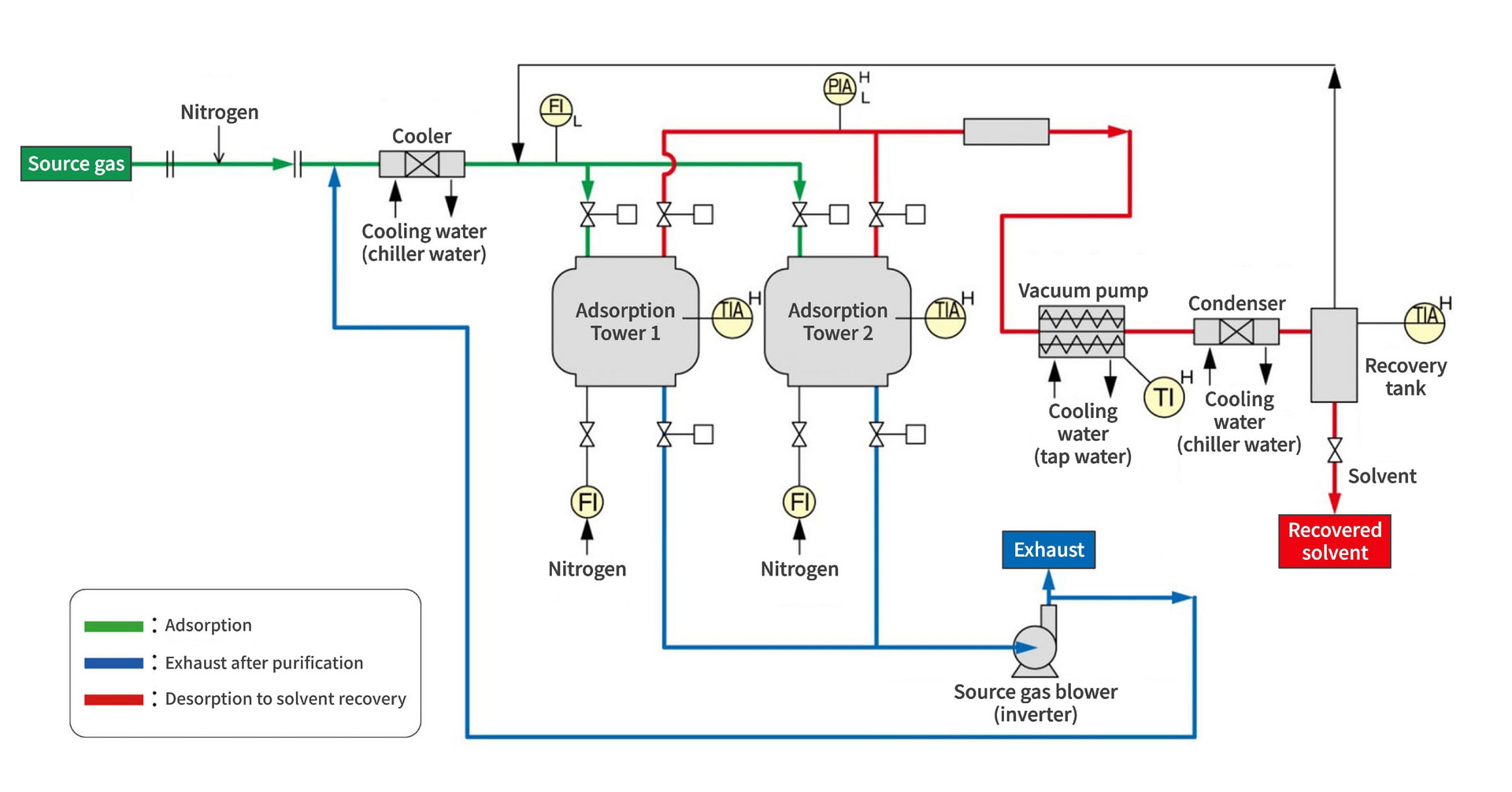

PSA type Solvent recovery system Basic Flow