Introduction of Steam Tube Dryer (Indirect Heating Dryer)

2025.05.08

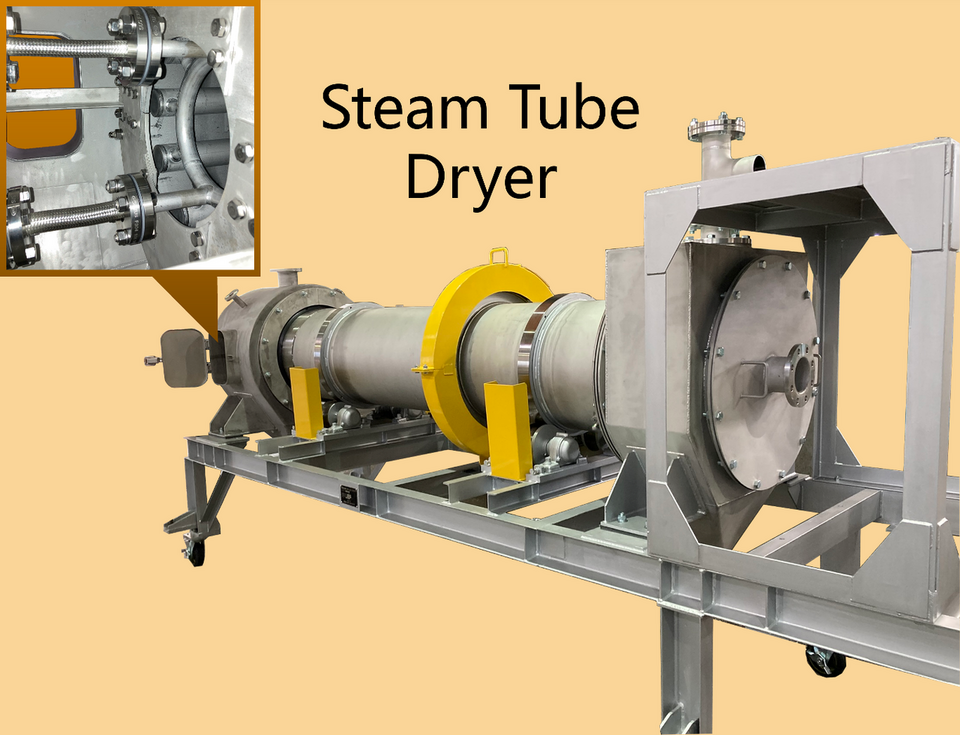

KURIMOTO introduces Steam Tube Dryer experimental machine.

This experimental dryer has passed the individual examinations for class-2 pressure vessels (JIS).

This continuous dryer system consists of the following components (example of combination).

(1) Fixed quantity feeder for raw material

(2) Steam Tube Dryer main unit

(3) Product collection container

(4) Air heater and blower for carrier gas heating

(5) Bag filter and exhaust fan for fine powder collection

Steam is supplied as a heat medium to the inner tubes inside the dryer.

The raw material (material to be dried) is fed into the heated dryer from the inlet side via the feeder.

And then moves to the outlet side by tilting and rotating the dryer, and the dried product is discharged.

Moisture evaporated by heating is exhausted out of the system from the inlet side by feeding carrier gas heated by an air heater from the outlet side.

Fine powder is collected by the bag filter and then discharged outside the system.

We offer testing services at our Machinery Technology Center.

If you are interested in a dryer with indirect heating and high thermal efficiency, please feel free to contact us.

Features

Indirect heating

Steam drying

Continuous operation

Specifications

Product name: Steam Tube Dryer

Body size: I.D. φ496 × L 2,500 mm

Body rotation speed: 3.4~14 min-1

Material: SUS304 (powder contact part), SS400

Motor: 2.2 kW 4P 1/29 BEIER-CYCLO Variator

Heat source: Saturated vapor

Heating temperature: Up to 160°C (0.6MPaG)

Heat transfer area: 4.2 m2 (0.42m2 × 10 tubes)