Introduction of the New Agitating Mill “FK40” (Dry Ultrafine Grinder)

2025.03.04

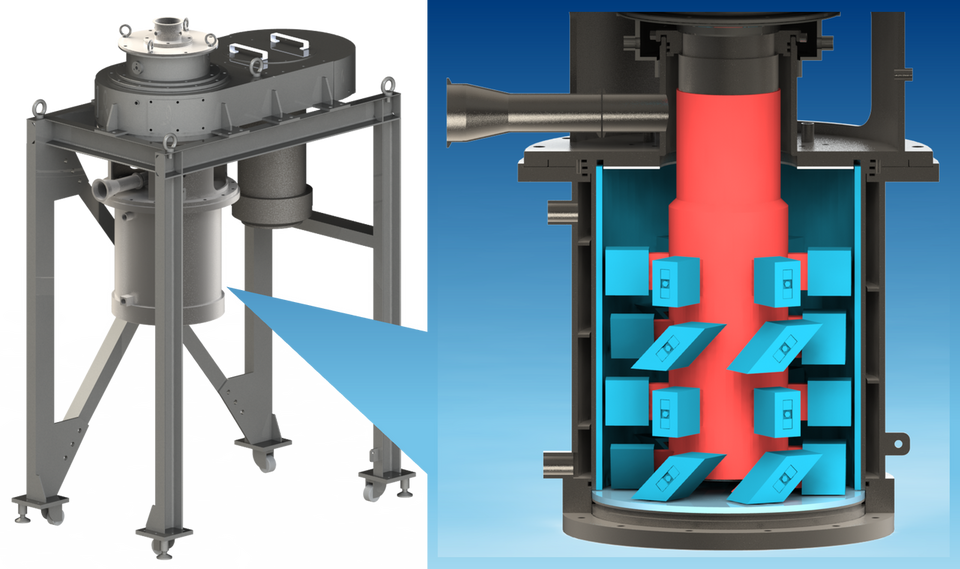

KURIMOTO has developed the FK40, a new agitating mill, designed to meet the growing demand for ultrafine pulverization (submicron level) and metal contamination-free processing.

This continuous type grinding system (example of combination) consists of a raw material feeder, the agitating mill itself, a bag filter for product collection, and a blower for pneumatic transport.

Inside the main unit, agitator blades rotate to agitate the grinding beads. The raw material (grinding objects), supplied from the top, is drawn into the machine through the hollow blade shaft and ground by the agitated beads. The finely ground product is then discharged from the top of the unit through pneumatic transport.

We offer testing services at our Machinery Technology Center. If you are interested in an efficient dry grinding system for ultrafine processing, please feel free to contact us.

Features

Ultrafine grinding (single-micron to submicron)

Metal contamination-minimizing design

Continuous operation

Specifications

Model: Agitating Mill FK40

Blade Speed: Up to 600 min-1

Material: SUS304, Alumina Ceramics (blue parts), Urethane Lining (red parts)

Motor: 11 kW, 6P VFD

Air Flowrate: Approx. 3 m3/min (reference value)

Capacity: Approx. 15 kg/h (reference value)

Required Raw Material Amount: Approx. 10 kg (reference)