Activated Charcoal

Introduction of Kneader

Product Name

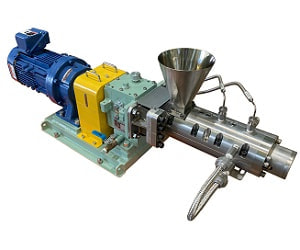

Twin-Shaft Continous Kneader 「KRC Kneader」

Advantages

- Faster cleaning and disassembling, due to the dividable body with a upper and lower section.

- Heat treatment through the jackets in the body. (Cooling with chilled water is also possible.)

- The double-bearing structure prevents contact between the paddles and the inner surface of the body. Therefore metal contamination is prevented.

KRC Kneader

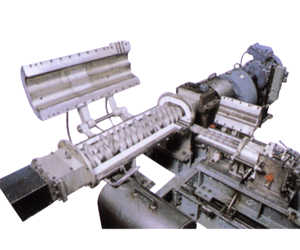

Inside view of the KRC Kneader

Introduction of Grinders

Product Name

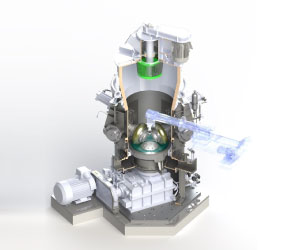

Vertical Roller Mill「VX Mill」

Advantages

- Fine milling with lower energy consumption (energy saving), due to the compression and shear force of the frictional grinding.

- By adjusting roller pressure and table speed, the operating conditions can be set to suit the target particle size.

- Low-vibration and low-noise operation due to the air gap between the rollers and the table.

VX Mill

Inside view of the VX Mill

Introduction of Calciners

External Heat Type Rotary Kiln (continous or batch)

- Reduction of calcining irregularities, due to regular hexagon shape of the body.

- Operation in various atmospheres is possible.

- Safe installation in hazardous areas, due to gas furnace as heating device.

Rotary Kiln (Electric Furnace Type)

Rotary Kiln (Gas Furnace Type)