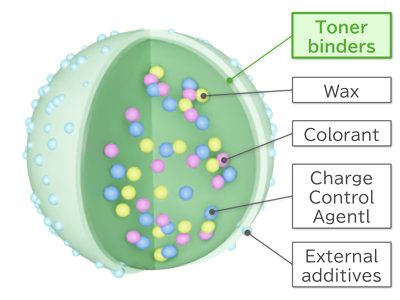

Toner binders

碳粉粘合剂 / Tonerbinder / 토너 바인더

Toner binder with improved low-temperature fixing, hot offset, grindability, and pigment dispersibility

Dry color toner, circuit board, label printing, etc.

Raw materials to be processed

※This process is just one example, and the manufacturing methods vary by company.

reaction &

pulverization

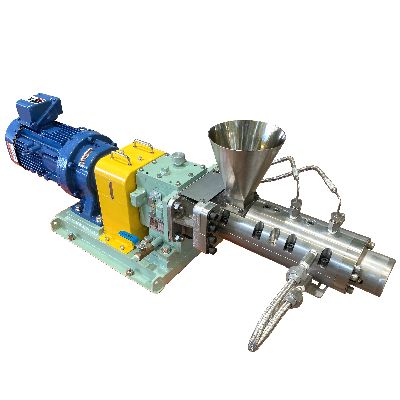

Kneading

It is required to knead the materials uniformly in a short time to prevent any deterioration of the raw materials.

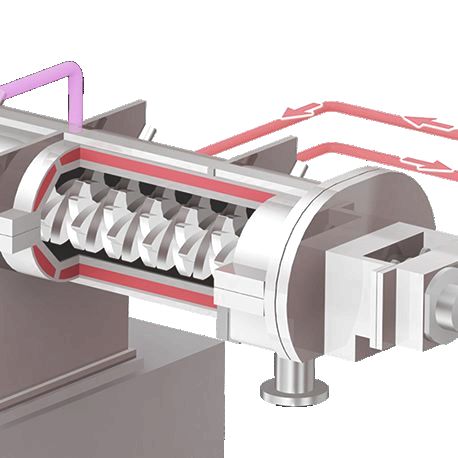

The twin-screw continuous kneader “KRC Kneader” enables the production of uniform and stable products in a short time, by the following mechanical characteristics.

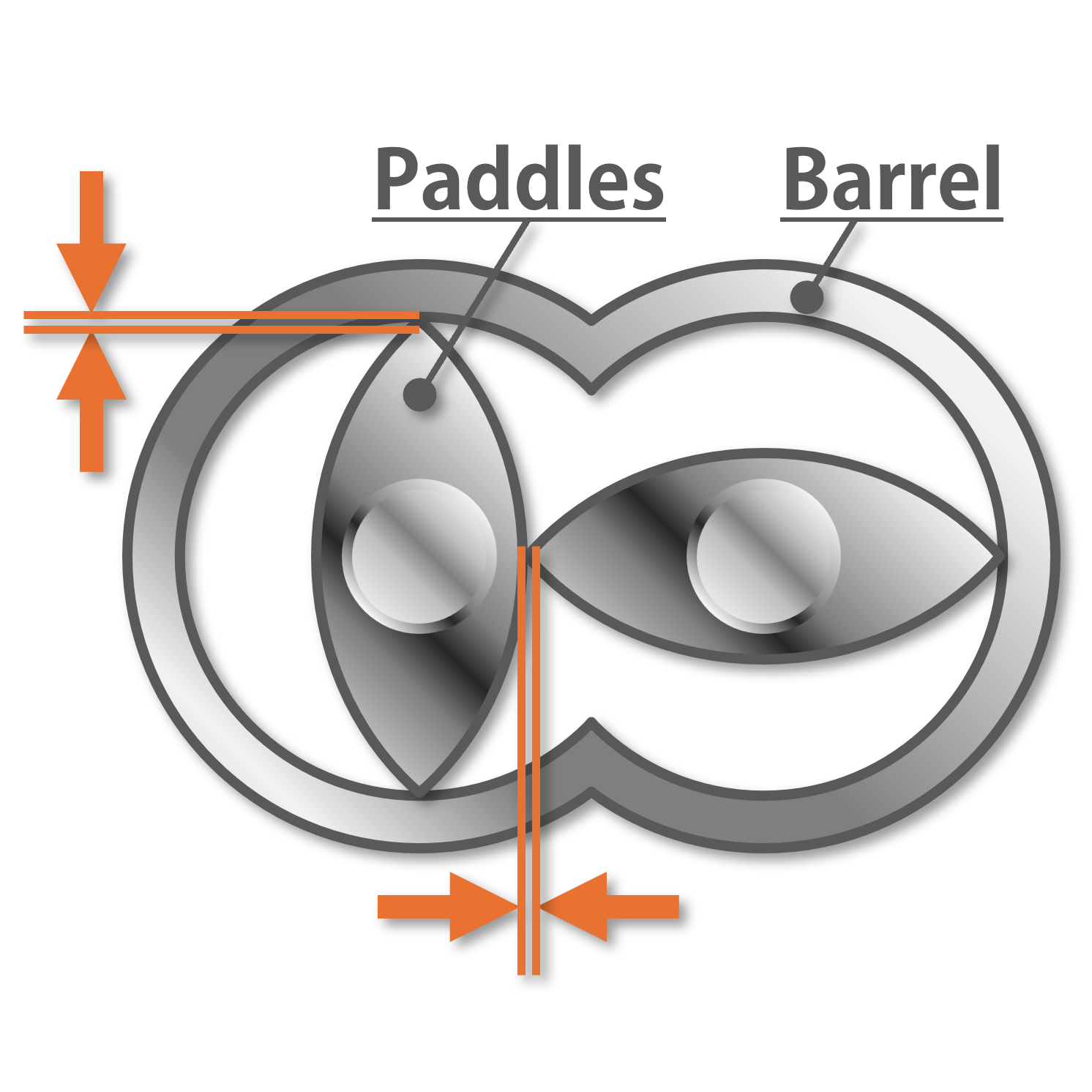

Excellent continuous kneading performance even achieved with a short L/D ratio

Excellent dispersion effect achieved by paddles with small clearances

Kneading temperature controlled by heating the jacketed barrel