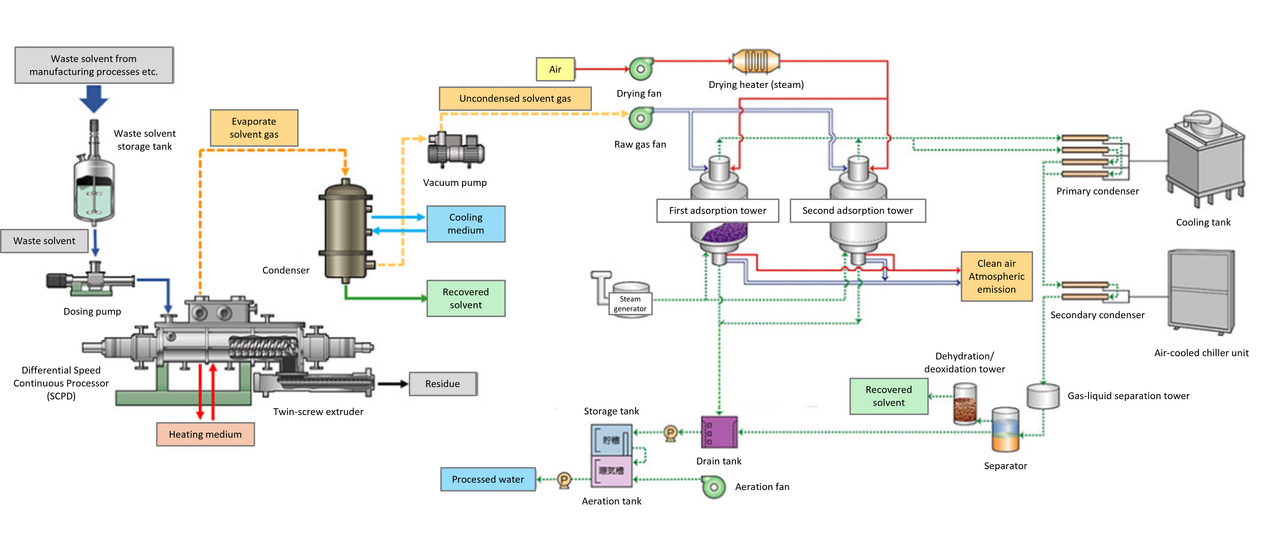

Residue separation and solvent recovery from waste solvents

Introduction of Dryers (desolvation purposes)

SC Processor Differential Speed Type「SCPD」

- Stable, continous operation and conveying even with highly viscous or adhesive materials as well phase changing materials.

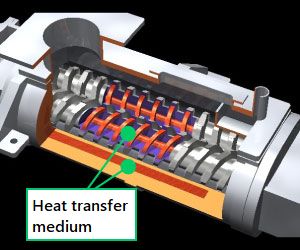

- A heat transfer medium can circulate in the body and the screws, providing a large heat transfer area even in smaller models.

- It is specialized in devolatilization and can be operated under depressure conditions.

Cross-sectional schematic diagram

of the SCPD

Inside view of the SCPD

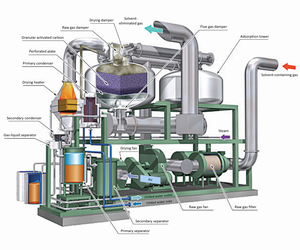

Introduction of Solvent Recovery Equipment

Product Name

Kurimoto Solvent Revcovery Equipment

Advantages

- By using coconut-shell activated carbon as an adsorbent, high density gas can be removed. The system is designed for a wide variety of solvents, including chlorinated and hydrocarbon solvents.

- The sufficiently thick layer of activated carbon enables a longer contact time with the gas, making it resistant to large fluctuations in the inlet gas density and keeping the outlet gas density low.

- For small air volume (~10m³/min) vacuum pumps and highly concentrated solvent exhaust, the newly developed " Kurimoto Solvent Revcovery Equipment" can reduce the water separation to a small amount. This is especially beneficial for water-soluble solvents.

Solvent Recovery Equipment

(steam desorption type)

Solvent Recovery Equipment

(vacuum desorption type)