TPU (Thermoplastic Polyurethane)

热塑性聚氨酯 / Thermoplastisches Polyurethan / 열가소성 폴리우레탄

Polyurethane thermoplastic elastomer with high strength, abrasion resistance, and flexibility

Mobile phone cases, shoes, automotive interiors, medical tubing, industrial hoses, various belts, etc.

Manufacturing process

※This process is just one example, and the manufacturing methods vary by company.

Stirring

To ensure stable operation and adjustment of the downstream processes, it is necessary to uniformly mix two raw materials with relatively low viscosity and different viscosity levels, while maintaining sufficient residence time through mechanical means.

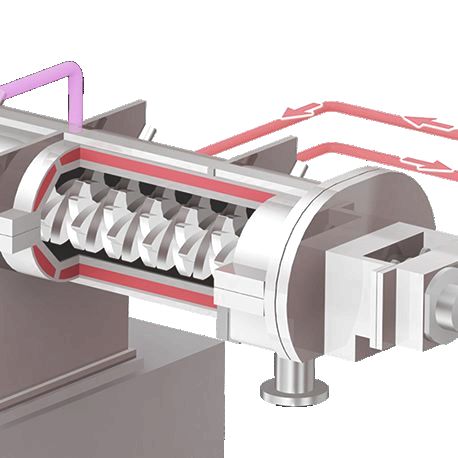

The twin-screw continuous kneader “KRC Kneader” enables the production of uniform and stable products with the specified crystal particle size, even when processing raw materials with different viscosities, by the following mechanical characteristics.

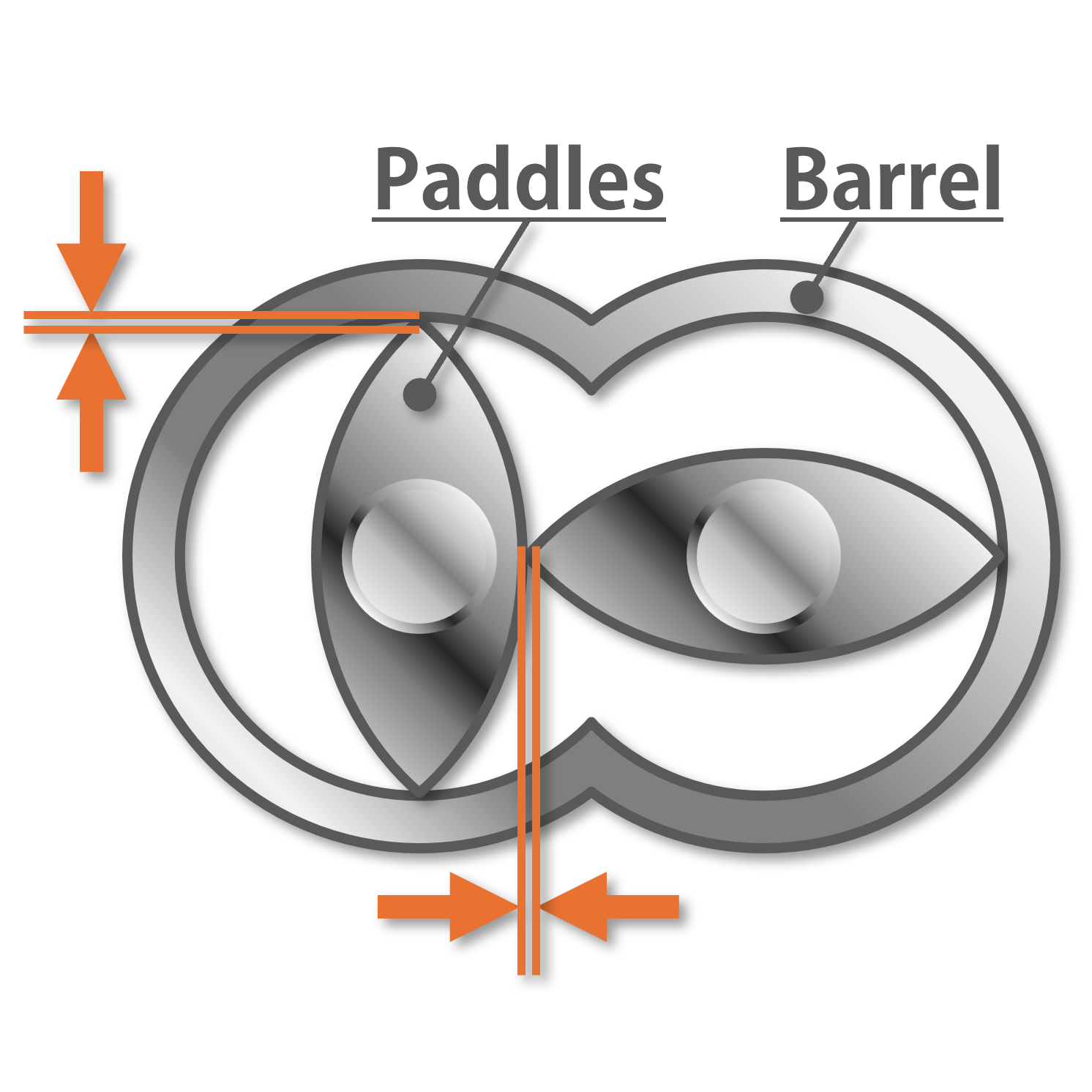

Excellent mixing performance achieved by paddles with small clearances

Heating provided by the jacketed barrel

aging