PPS (Polyphenylene Sulfide)

聚苯硫醚 / Polyphenylensulfid / 폴리페닐렌 설파이드

A thermoplastic super engineering plastic with high heat resistance, cold resistance, and chemical resistance, which can be combined with glass fiber to improve mechanical properties.

Automotive parts, electrical components, household electrical appliances, pump and valve parts, lightweight structural materials

Manufacturing process

※This process is just one example, and the manufacturing methods vary by company.

reaction

recovery

During this process, the raw materials undergo phase transitions (from low-viscosity liquid to high-viscosity liquid, then chunk and powder), resulting in significant changes in their state. In addition, since the recovered organic solvents have relatively high boiling points, careful control of temperature and vacuum conditions is required to improve productivity.

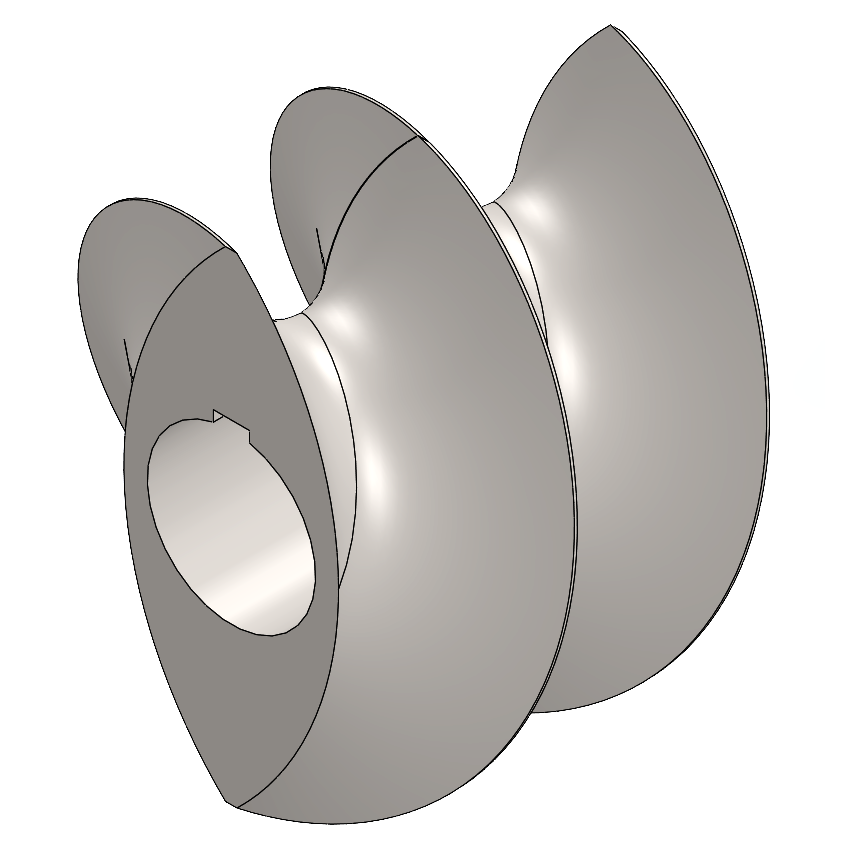

The twin-shaft indirect heating dryer “Differential-Speed SC Processor” can stably process raw materials that undergo phase transitions or have high boiling points by the following mechanical characteristics.

Smooth conveying of high-viscosity materials achieved through the self-wiping function

Large heat transfer area ensured by the jacketed barrel and hollow shafts

Efficient processing of raw materials with high boiling points achieved through vacuum operation

bulk density

When a liquid binder is added for granulation, a subsequent drying process becomes necessary, which may increase labor and costs, potentially reducing productivity.

The mixing and compression granulating machine - “MRCP Roller Compactor” enables binder-free granulation thanks to the following mechanical characteristics.

Raw materials are fed and pressed into the rollers by screws and paddles.

Discharged in sheet form through roller compression

Crushed into granules by a coarse crusher, then classified and adjusted for particle size