PGA (Polyglycolic Acid Resin)

聚乙醇酸树脂 / Polyglykolsäureharz / 폴리글리콜산 수지

A biodegradable plastic with high mechanical properties, including tensile strength etc. that can withstand high-temperature environments exceeding 100°C

Medical sutures, implant parts, sealing materials for shale gas and oil drilling, fisheries and agricultural materials, etc.

Manufacturing process

※This process is just one example, and the manufacturing methods vary by company.

Kneading

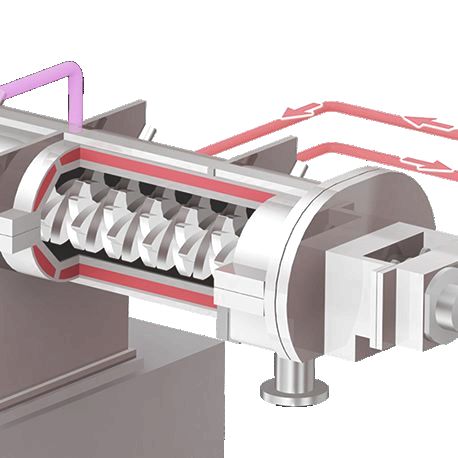

The twin-screw continuous kneader “KRC Kneader” enables the production of uniform and stable products under high temperatures by the following mechanical characteristics.

The twin-screw continuous kneader “KRC Kneader” enables the production of uniform and stable products even at under high temperatures by the following mechanical characteristics.

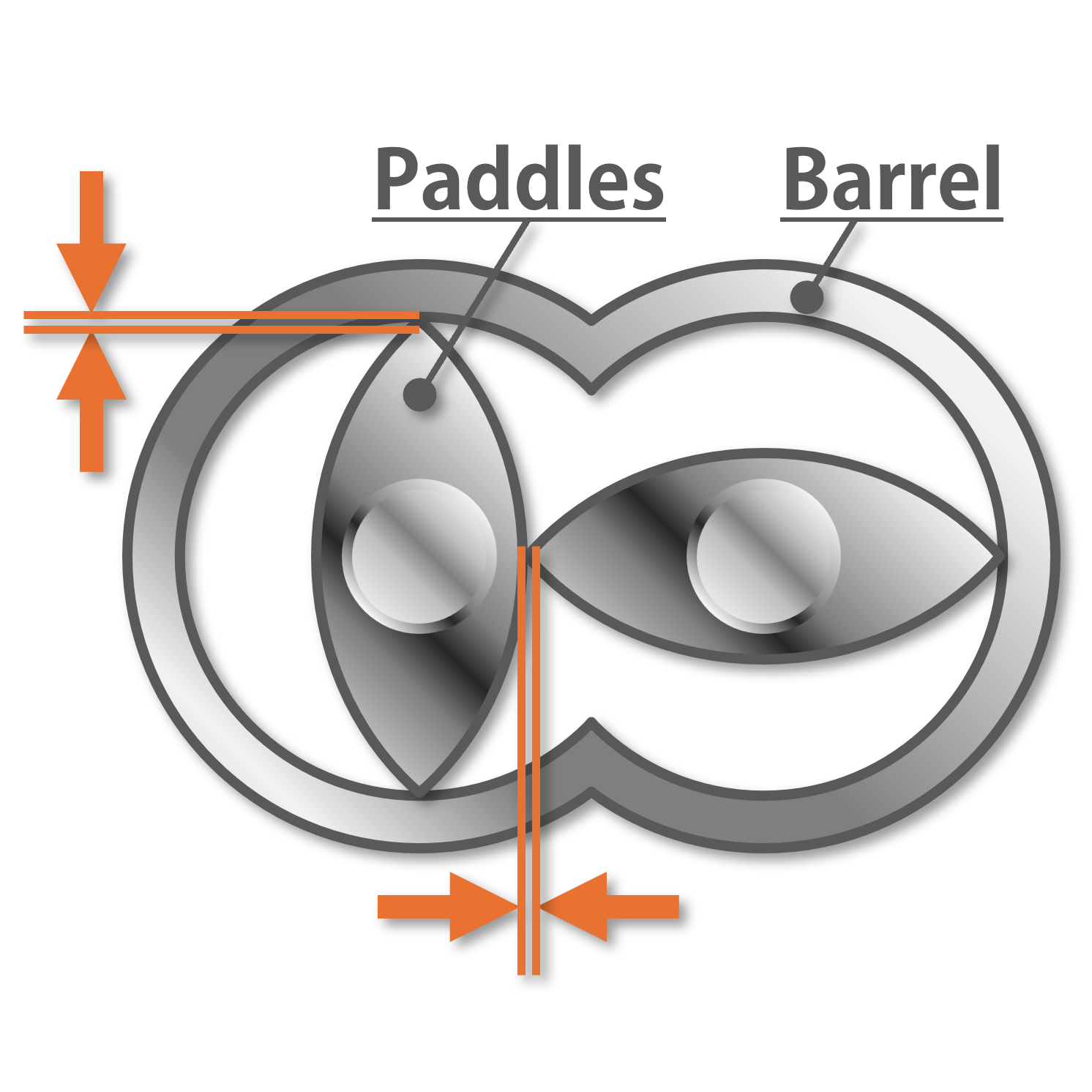

High shearing force generated by paddles with small clearances

High-temperature operation achieved by heating the jacketed barrel

Crystallization

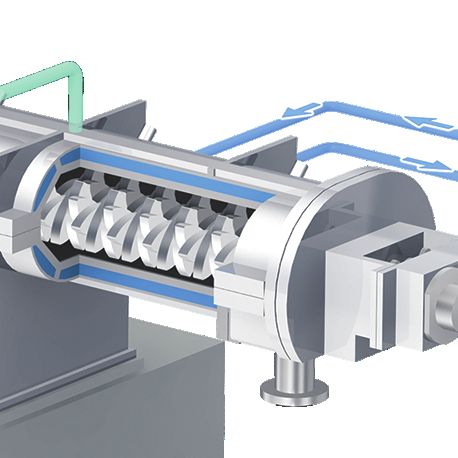

Due to the increase in viscosity from cooling and the backpressure generated by the discharge die, high power and extrusion pressure are required.

The twin-screw continuous kneader “KRC Kneader” enables the production of uniform and stable products even under high-load conditions, thanks to the following mechanical characteristics.

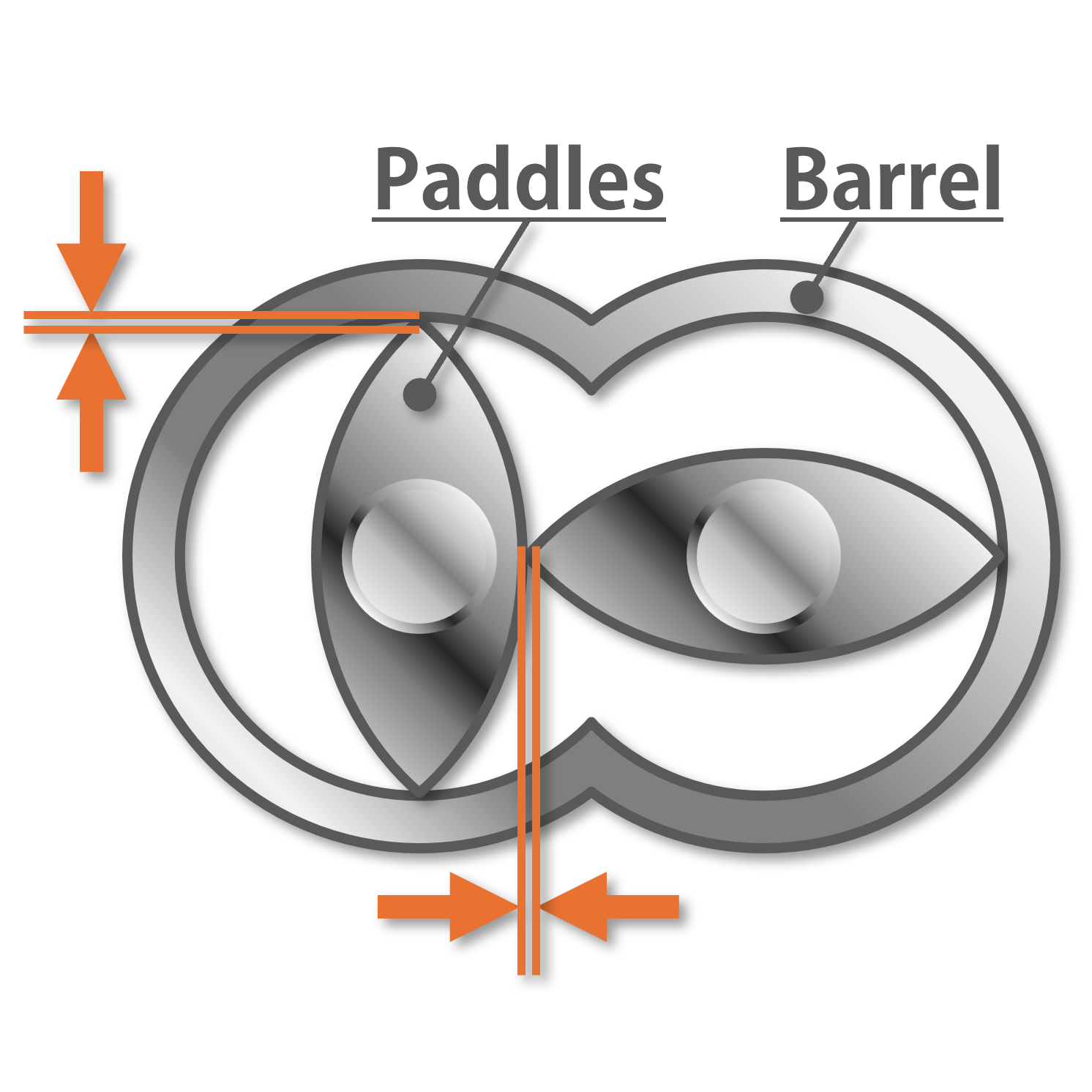

High shearing and extrusion force generated by paddles with small clearances

Cooling and removal of kneading heat achieved through the jacketed barrel

process