Carbon nanotube(CNT)

Introduction of Kneader

Product Name

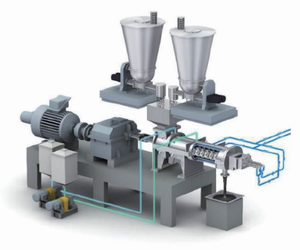

Twin-Shaft Continous Kneader「KRC Kneader」

Advantages

- Outstanding continuous kneading performance due to short L/D ratio.

-

No variations in the mixing ratio, due to

high dispersion and agitation capabilities. - Abrasion-resistant specification available.

KRC Kneader

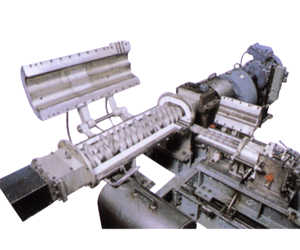

Inside view of the KRC Kneader

Introduction of Grinders

Product Name

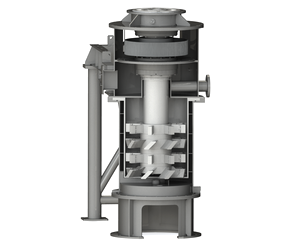

Dry Type Vertical Bead Mill「Agitation Mill」

Advantages

- Fine milling at several µm level.

- Central raw material feeding ensures that the material passes the grinding area.

- Efficient and fine grinding of materials with low specific gravity is possible.

Agitation Mill

Agitation Mill FK80

Introduction of Dryers

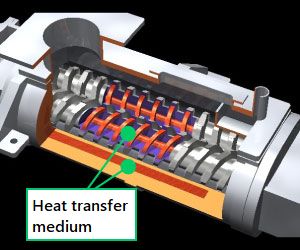

Twin-Shaft Indirect Heating Type Dryer「CD Dryer」

- Efficient agitation due to specially designed discs enable high termal processing.

- Various operation modes, like iner gas circulation, heating and cooling and operation under decompression are possible.

- Different heat transfer mediums (heat transfer oil, steam, hot water, industrial water, various refrigerants, etc.) can be used.

CD Dryer

Inside view of the CD Dryer

during an experiment

Introduction of Dryers (devolatilization purposes)

SC Processor Differential Speed Type「SCPD」

- Stable, continous operation and conveying due to twin-shaft self-cleaning type screws, even with highly viscous or adhesive materials as well phase changing materials.

- A heat transfer medium can circulate in the body and the screws, providing a large heat transfer area even in smaller models.

- It is specialized in devolatilization as well as solid-liquid separation and can be operated under depressure conditions.

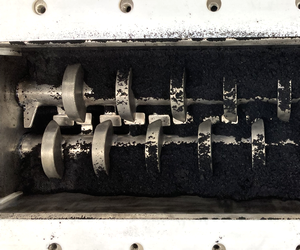

Cross-sectional schematic diagram

Inside view of the SCPD