Catalysts (zirconia, alumina)

Introduction of Calciners

External Heat Type Rotary Kiln (continous or batch)

- Reduction of calcining irregularities, due to regular hexagon shape of the body.

- Operation in various atmospheres is possible.

- Safe installation in hazardous areas, due to gas furnace as heating device.

Rotary Kiln (Electric Furnace Type)

Rotary Kiln (Gas Furnace Type)

Introduction of Grinders

Product Name

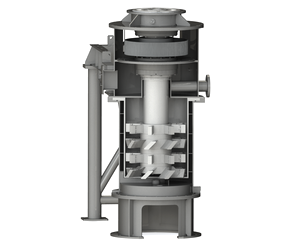

Dry Type Vertical Bead Mill「Agitation Mill」

Advantages

- Fine milling at several µm level.

- Central raw material feeding ensures that the material passes the grinding area.

- Efficient and fine grinding of materials with low specific gravity is possible.

Agitation Mill

Agitation Mill FK80

Introduction of Grinders

Product Name

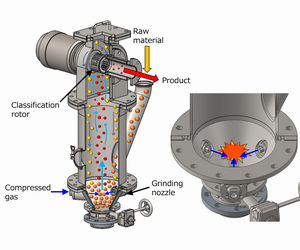

Airflow Micro-Grinder「Cross Jet Mill」

Advantages

- Fine milling at several µm level and sharp-peaked particle size distribution.

- Metal contamination-free specification available, by using ceramic parts for the raw material contact areas.

- Grinding in an inert gas atmosphere is possible.

Jet Mill

Cross-sectional schematic diagram

of the Jet Mill

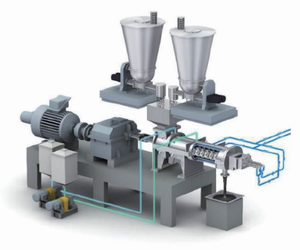

Introduction of Kneader

Product Name

Twin-Shaft Continous Kneader「KRC Kneader」

Advantages

- Outstanding continuous kneading performance due to short L/D ratio.

- Even kneading of raw materials and binder for strong moldings.

- Abrasion-resistant specification available.

KRC Kneader

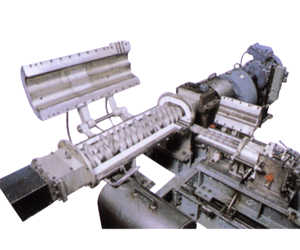

Inside view of the KRC Kneader