At our Machinery Technology Center, we utilize our deep know-how of self-cleaning and continuously processing twin-screw machinery and show you the possibilities of a continuous production of liquid, powder and slurry materials.

At Machine Technology Center, we have cultivated utilizing the know-how of the "selfcleaning" twin-screw continuous processor, we propose "continuous" process of raw materials for liquids, powders, and slurries.

Features

- Twin-screw continuous type

- Self-cleaning

- Operation under decompression (133PaA~)

- Operation at high temperatures (up to 350℃)

- Handling of high-viscosity raw materials (up to 5,000Pa・S)

Usage

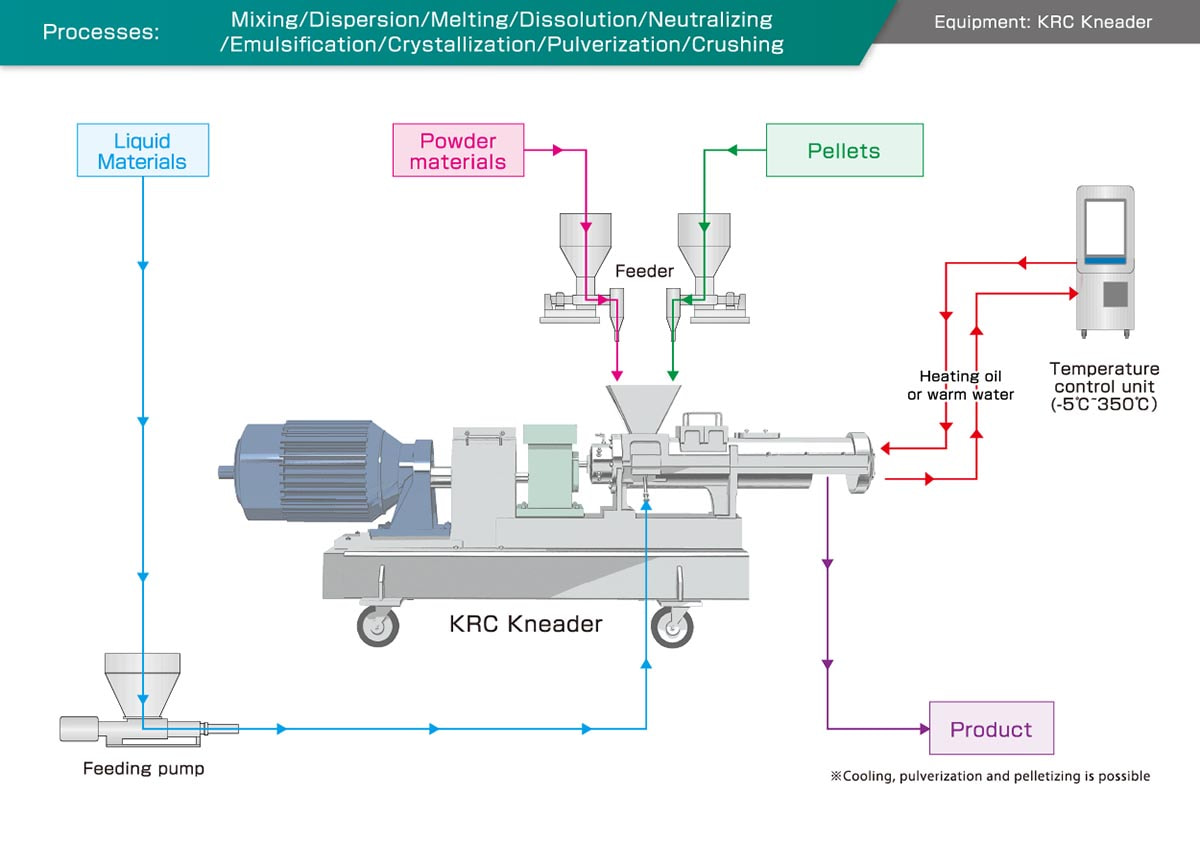

-

Kneading、

Dispersion、

Melting、

Dissolution、

Neutralization、

Emulsification、

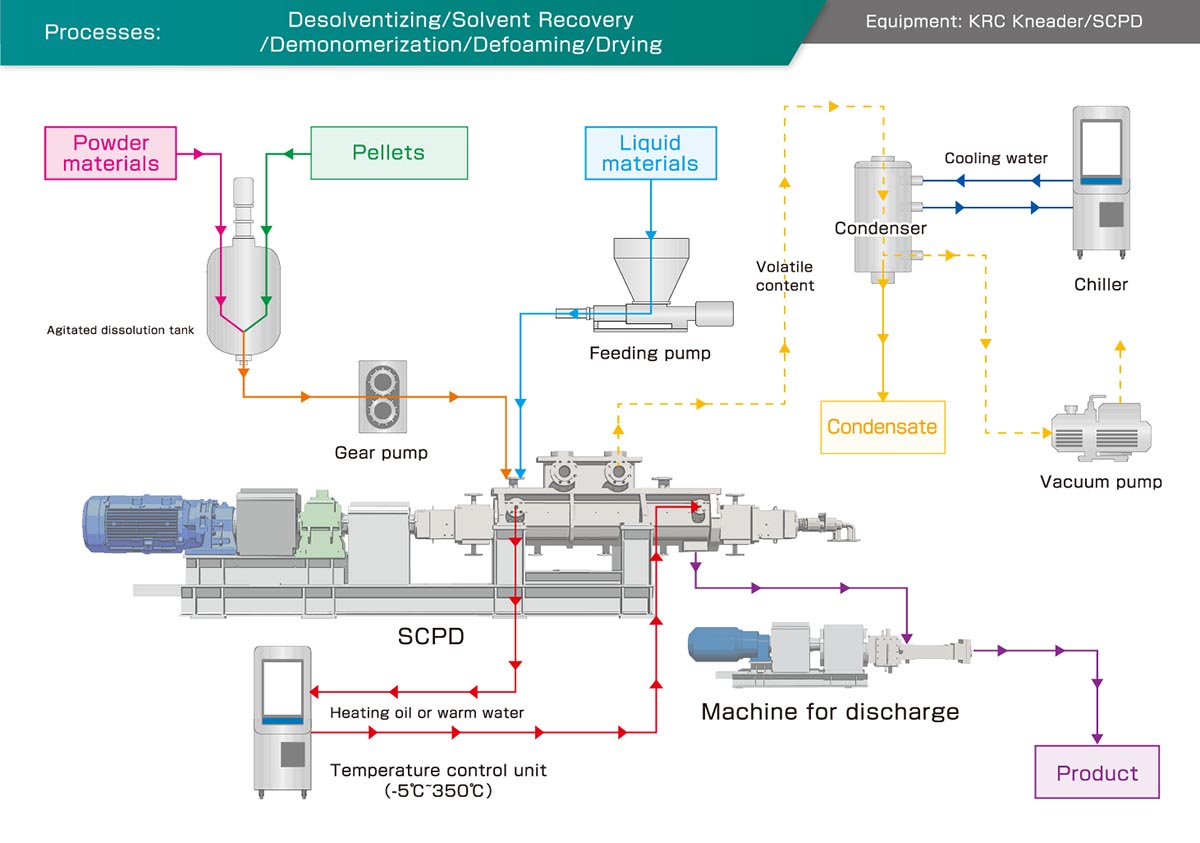

Crystallization、 Grinding、 Pulverization、 Desolventing、 Solvent recovery、

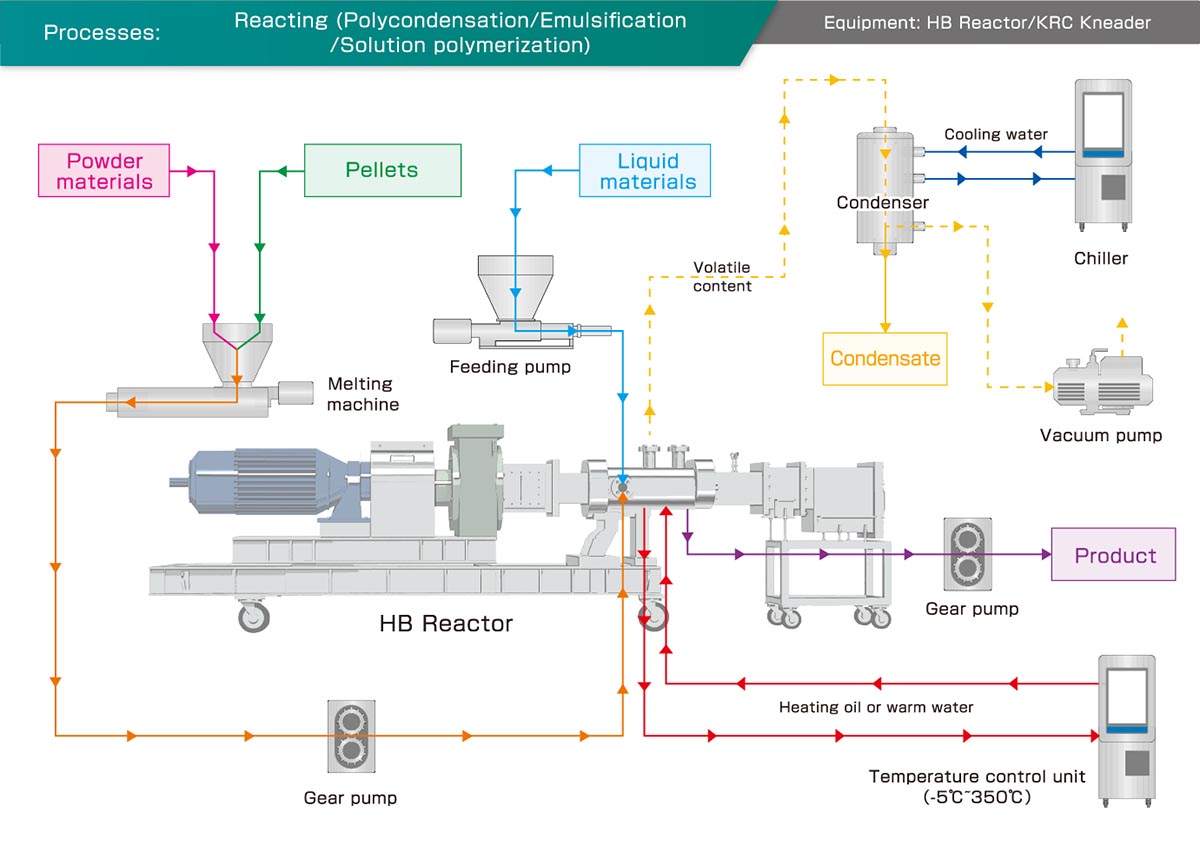

Drying、 De-monomerization、 Defoaming,、 Reacting, Cooling

Processable materials

-

Engineering plastics, Electronic materials, Encapsulants, Thermosetting resin, Fibers, Rubber, Food, Cellulose,

Pharmaceuticals, Cosmetics, Batteries, Catalysts, Composites, Adhesives, Sealants, Ceramics, Paints, Toners,

Test flow (example)

Continuous Kneader, Reactor and Dryer

Introduction of testing equipment

Continuous Kneader, Reactor and Dryer

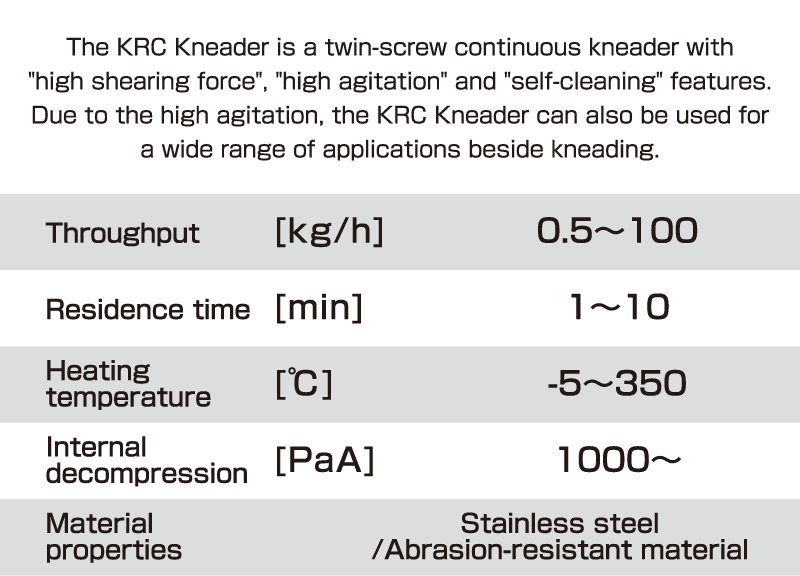

Twin-screw continuous kneader/KRC Kneader

Specifications

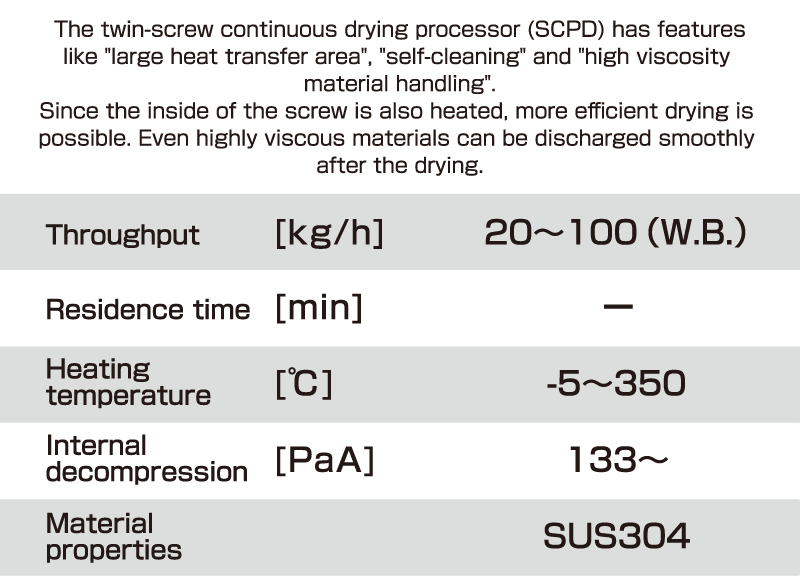

Twin-screw continuous drying processor/SCPD

Specifications

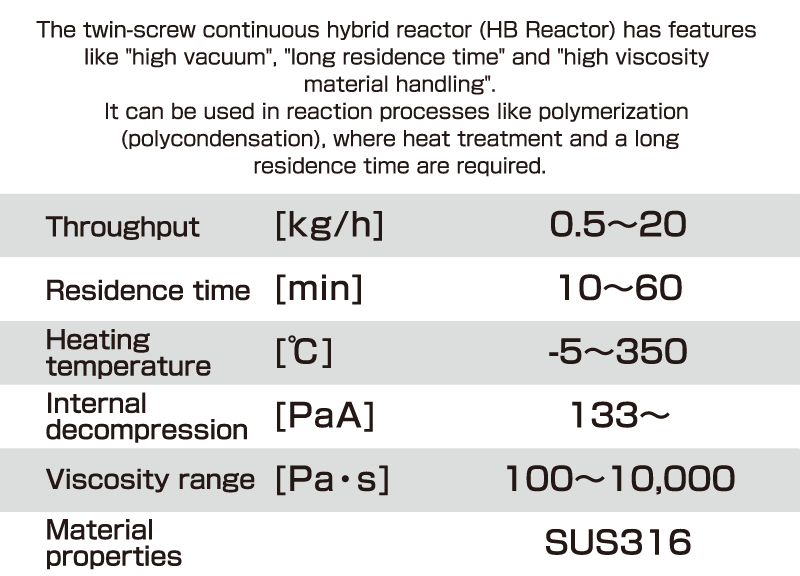

Twin-screw continuous hybrid reactor/HB Reactor

Specifications